It’s Worth Another Look

It is not uncommon to know you have a problem with a fuel system, but cannot seem to find the solution. This is especially true with the problems created by microbiological contamination. In March of last year, we made a post and think it is worth taking another look at.

Repost from March 16, 2022 – How to Find the Problem in Your Fuel Tank

Sampling and More

Recent studies on retail and commercial fueling sites show the poor condition of both fuel and fuel systems. Only a small percentage of owners and managers say they regularly manage their systems. Not surprising that almost all of the diesel fuel samples taken had some level of microbial contamination as well as other issues. While the problems associated with microbial contamination are well documented, many operators still don’t understand the importance of managing fuel systems. Over the next several weeks, our posts will address the problems and solutions to fuel system management. In this post, we will address the challenges of fuel sampling and show how system inspections and analysis can help determine the problem in your fuel tank.

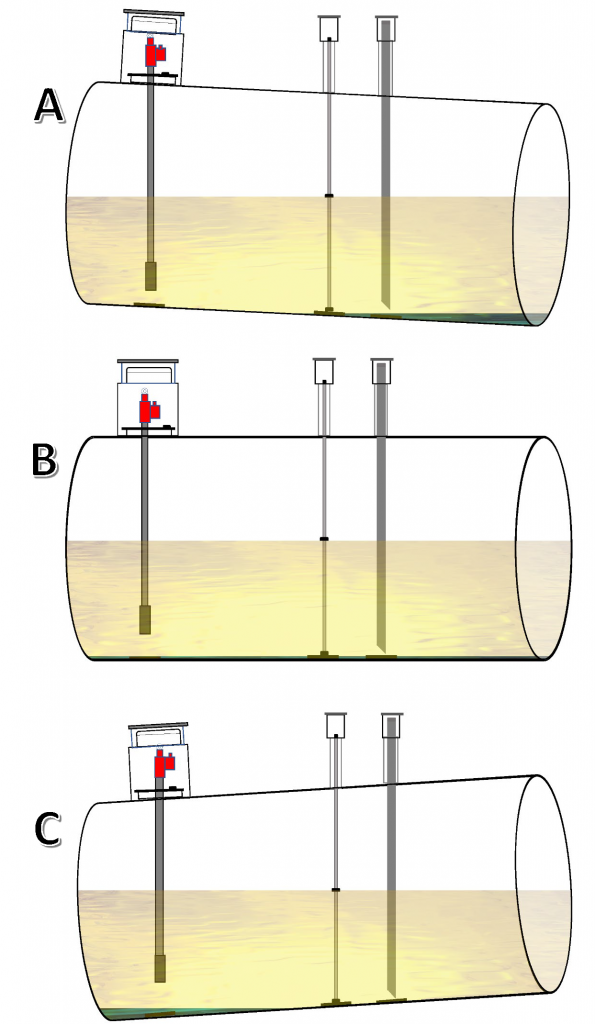

Fuel sampling sounds straightforward. But it isn’t. Because microbial contamination in fuel is heterogenous (non-uniform), a single sample never provides a complete picture of what is going on in the tank. Fuel samples are never representative. However, they are diagnostic. The images below show the potential difficulty in obtaining a single sample for diagnostic purposes.

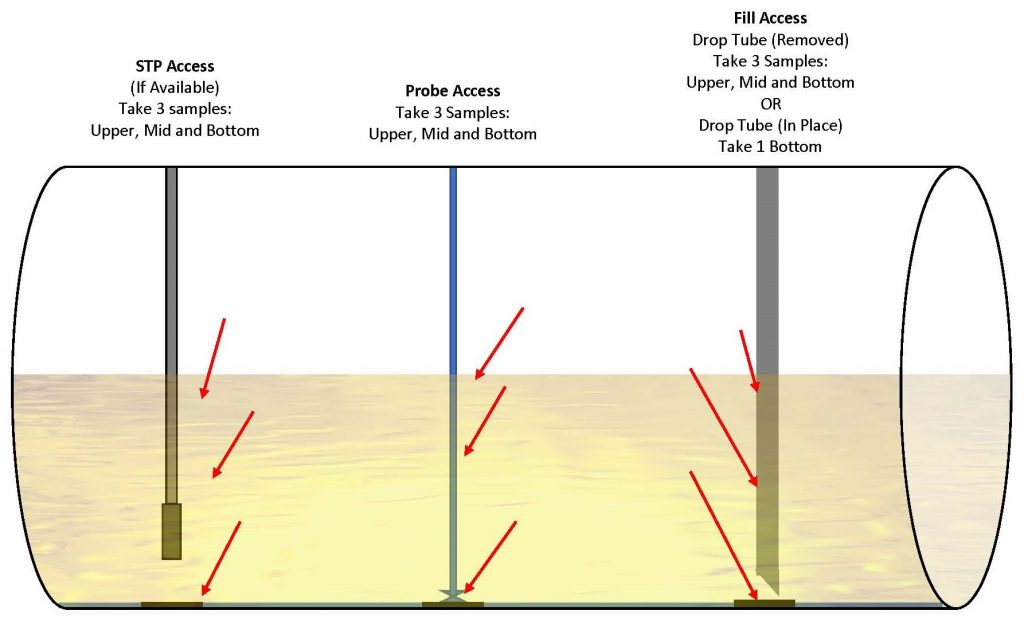

It is easy to see how difficult finding a sample to diagnose a problem may be an issue. Taking a cross-section of samples is a good start. The illustration below shows the different places samples might be taken with proper access. Ideally, six to nine samples are adequate.

Using a bacon bomb style sampler, take as many samples as possible. Choosing the right sampler is important. One that has a plunger assembly for taking bottom samples and pulling middle to upper layer samples is vital. Sample size is another important feature. Once you have your samples, they will likely differ. I often share the below pictures to show the stark differences between samples taken from the same tank, the same time and different places.

Imagine pulling only one sample and it looked like the one on the right. You might be left with the impression that there were no problems in the tank. Or the one of the left, you might think the entire tank of fuel was bad. Both impressions would have been misleading to say the least. In this particular instance, the mid and upper layers were rather clean, though still contained enough microbial contamination to be a concern. The bottom layer contained serious biomass and high microbial counts. In the end, the tank was treated with a shock dose of Biobor JF and left to soak. Then was cleaned to remove the dead bugs, biomass and other contaminants.

Because microbial contamination is heterogenous, it is easy to get mixed results when sampling and testing fuel. It is not uncommon to see results with low or near zero contamination in one part of the tank and severe contamination in another part. It is also not entirely uncommon to have a group of samples look and test with passing results, yet still have a major systemic problem. Sampling provides one part of the picture. Fuel system inspections and system failure analysis are the others.

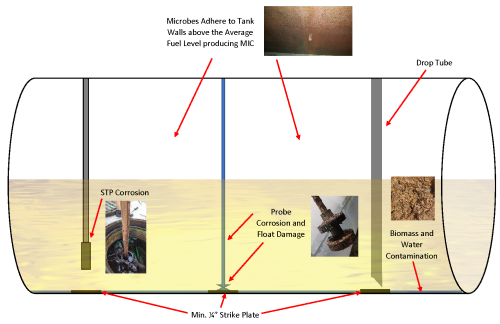

Regular fuel system inspections are an important part of fuel system management. In this case, inspecting for corrosion is the priority. Excessive or accelerated corrosion is a tale-tale sign of microbial influenced corrosion.

If your samples are clear but you have corrosion like the pictures above, have a serious microbial issue out of reach for accurate sampling. Numerous studies confirm to connection between microbial contamination and moderate to severe system corrosion.

What else can signify a problem in the tank? There are operational issues associated with microbial contamination. Take a look at the below list.

Fuel System Operational Issues Due to Microbial Contamination

- Premature dispenser filter replacement

- Corroded dispenser filters (upon replacement)

- Dispenser meter corrosion (premature replacement)

- Corroded STP components

- Frequent or repeated proportional valve replacements

- Slow flow dispenser issues

- Premature or frequent dispenser hanging hardware failure

- Leak detector failure

- Shear valve failure

- Line and tank failure

- Probe malfunctions and failures

- Water probe false readings

Fuel system analysis is something often overlooked. If you are having any of the operational issues listed (or several) and have corrosions issues, even without fuel samples it is safe to say you have microbial contamination causing the problems. So let’s put it all together in a simple list:

How to Determine What is in Your Tank

- Take fuel samples from as many access points as possible from bottom, mid and upper layers. Determine what you can from the samples. If the fuel is contaminated then you know you have a problem, but keep working through the process.

- Inspect the fuel system for corrosion issues. If you find moderate to severe corrosion or have had accelerated corrosion, then you have a problem. If you also have contaminated fuel samples, this confirms how serious it is.

- Do a simple system analysis by taking your last three months service receipts to determine if any of the operational issues on the previous list were part of the problem. If so, it is strong indication that you have serious microbial contamination.

What is the answer, use Biobor JF to kill the microbial contamination….

Share the Post