Biofilms are microbiological communities found throughout the earth in many different forms. If you have ever gone hiking and crossed a stream, the slimy layer growing on the rocks is biofilm. The layer of slime that clogs plumbing lines is biofilm. Dental plaque is biofilm. It can be found on most surfaces that contain moisture and nutrients. Microbiological contamination in a fuel system, left untreated, frequently results in biofilm formation including on tank walls and tops where condensation often forms. In this post, we introduce biofilm basics to help you understand why it is important to effectively control its formation.

Biofilm Structure

Left unchecked, microbes form a multicellular structure that is slimy, gummy and mucus-like. This biofilm structure is held together by molecular strands of polymeric microbial excretions called extracellular polymeric substances or EPS.

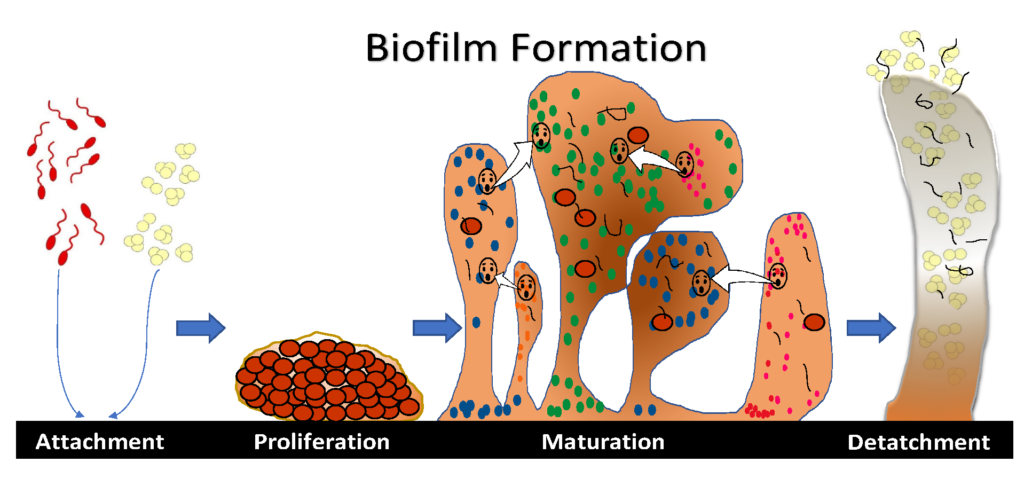

The image below shows the biofilm cycle of formation.

Figure 1 shows the formation and lifecycle of biofilms. Microbial contamination, consisting of bacteria and fungi, will eventually attach themselves to any structure that is moist – tank walls and sides, probes and risers to name a few. Once attached they begin to proliferate, feeding off the nutrients in the fuel tank until they reach maturity. The last stage of biofilm formation is detachment where microbes detach and disperse throughout the fuel system, contributing to further system contamination and biofilm formation elsewhere.

Biofilm structure is complex, made up of organic biomolecules including:

- Lipids include fats, oils and waxes. They are insoluble in water but soluble in organic solvents such as hydrocarbons.

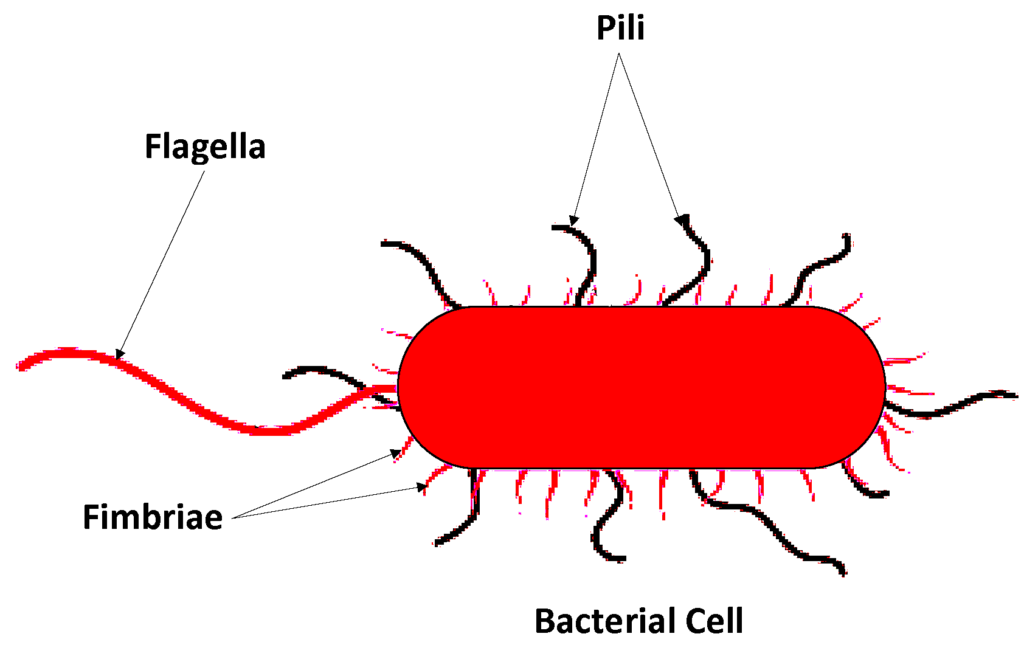

- Proteins are organic compounds including cell appendages, like flagella, pili and fimbriae (Figure 2). Proteins help in the attachment of microbes to surfaces and the stabilization of the biofilm structure.

- Carbohydrates aid in adhesion and protection during biofilm formation. They are mainly sugar molecules called polysaccharides that act as the molecular glue helping microbes to stick to each other and surfaces.

- Nucleic acids include deoxyribonucleic acid (DNA) and ribonucleic acid (RNA). They are critical components, providing protection to microbes from environmental dangers.

Within the biofilm structure there can be found zones that contain high microbial populations and zones that have little to none. There are channels within the structure that serve as nutrient and metabolite pathways, feeding the microbial community. Biofilms are in a constant state of change as seen in Figure 1. The detachment phase can happen due to disruption from events like a fuel drop where fuel flow might be the cause. It can also happen naturally as the cellular community releases cells into the fuel system. Either way, as long as there is water, biofilms can and will continue to form in a fuel system.

Microbial Communication

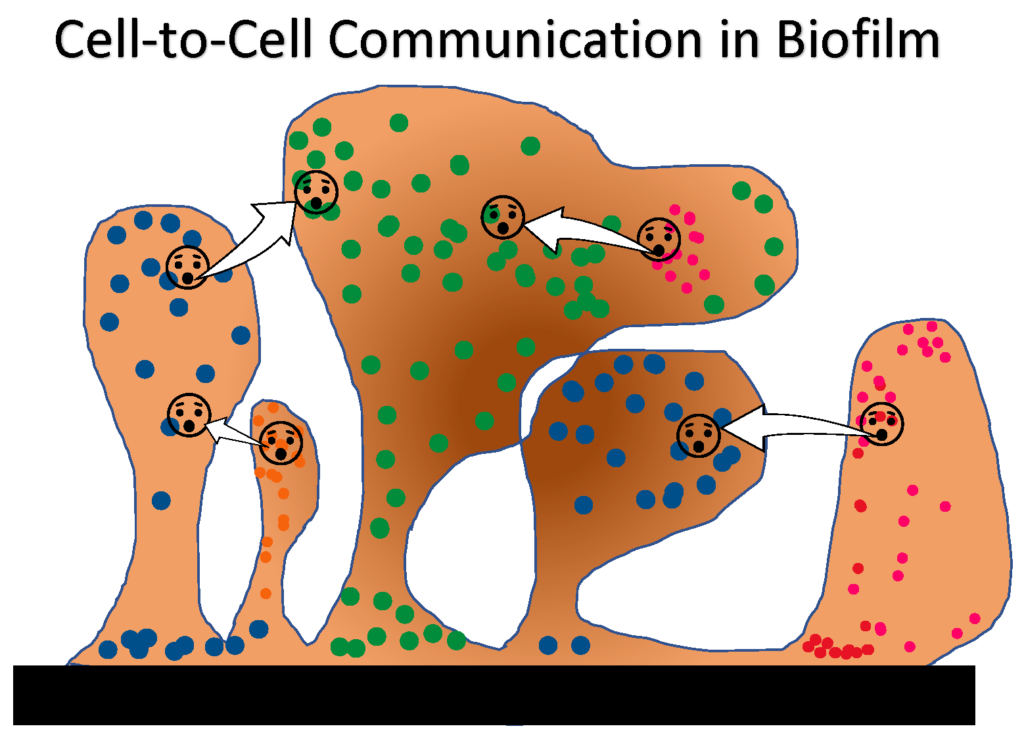

At each phase of biofilm formation, cell-to-cell communication, called quorum sensing, helps to shape and maintain the structure (Figure 3). Communication signals are sent via chemical cues. Cells produce EPS which act as chemical signals, inviting other cells to join. Additional signals continue to be sent out, aiding in the formation of the biofilm and protection of the cells. As the environment changes in the fuel system, this molecular communication plays a significant role in biofilm production. Biofilm structure is dependent on cell-to-cell communication. Each microbial cell is affected by this communication.

Contamination Removal

Biofilms and high levels of contamination are usually found in bottoms-water and interface layers on the bottom of the fuel tank or along the sides and top of the tank where condensation encourages microbial growth. They can also form in baffled areas, fuel lines and hard to reach areas of the system. Remember, water is always present in fuel in some form. A very thin and seemingly insignificant biofilm of 1-mm on a tank wall or top is 100 times the thickness of fungi and can be up to 1000 times thicker than the longest bacteria, providing a protective barrier over the microorganisms.

Using a quality biocide is helpful at breaking down the biofilm layers, a well developed biofilm structure will often need to be physically removed through a tank cleaning process. Once removed, it is important to use Biobor JF to ensure the microbial contamination is effectively killed. Because it is fully soluble in fuel, it will flow through the system, killing any remaining microbes and reducing the possibility of new biofilm formation.

An effective approach to disinfecting a heavily contaminated fuel systems includes:

- Apply a shock dose of Biobor®JF, preferably using some method of application or agitation that will help distribute the biocide adequately throughout the fuel. Fill the tank to the highest level. The biocide will only work where it touches.

- Allow the biocide time to work. Soak times need to be increased with higher levels of contamination, giving the biocide time to penetrate biofilms.

- Physically clean the fuel, fuel system and lines. When filtering the fuel, it should be turned over a minimum of 3 times, preferably 7 times to remove all of the flocs (chucks of biomass) and dead organisms once the system has been shock treated.

- Retreat the fuel with Biobor JF during the last phase of filtering to ensure good mixing.

A Case for Regular Biocide Use

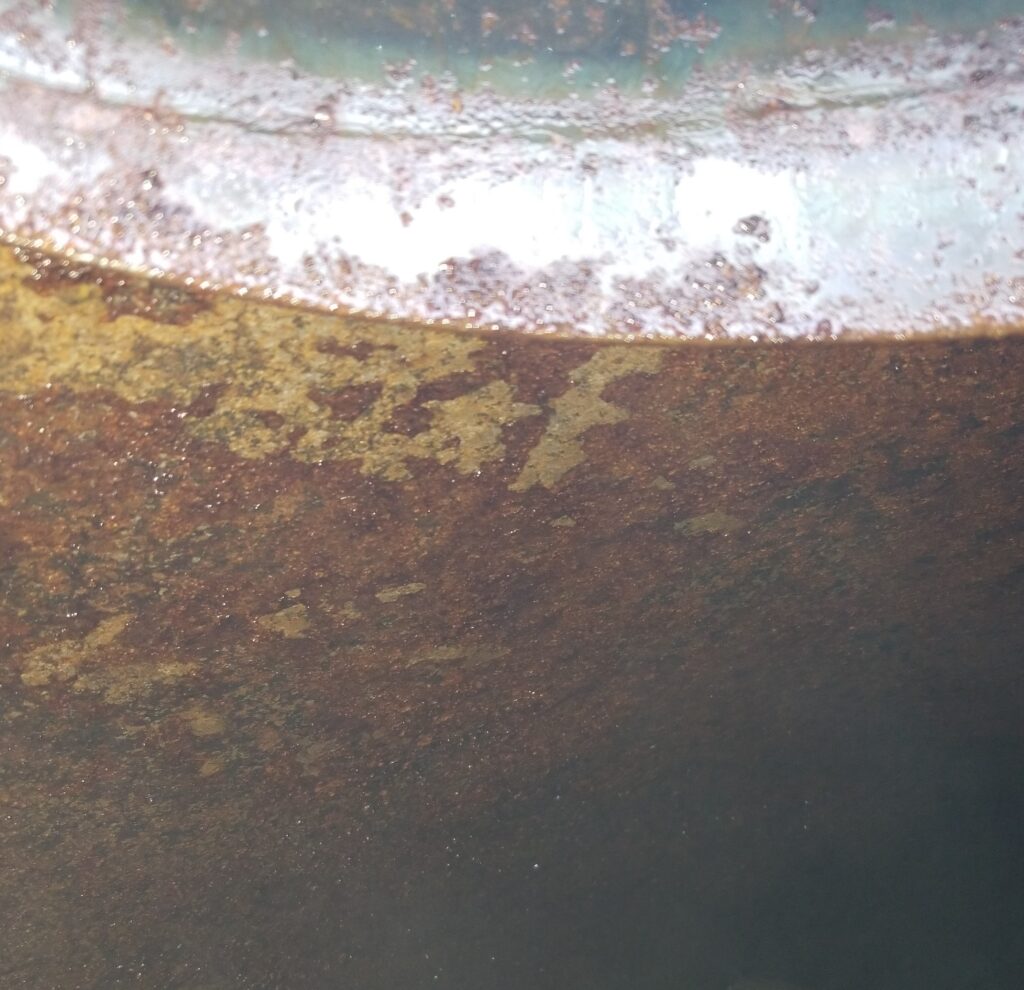

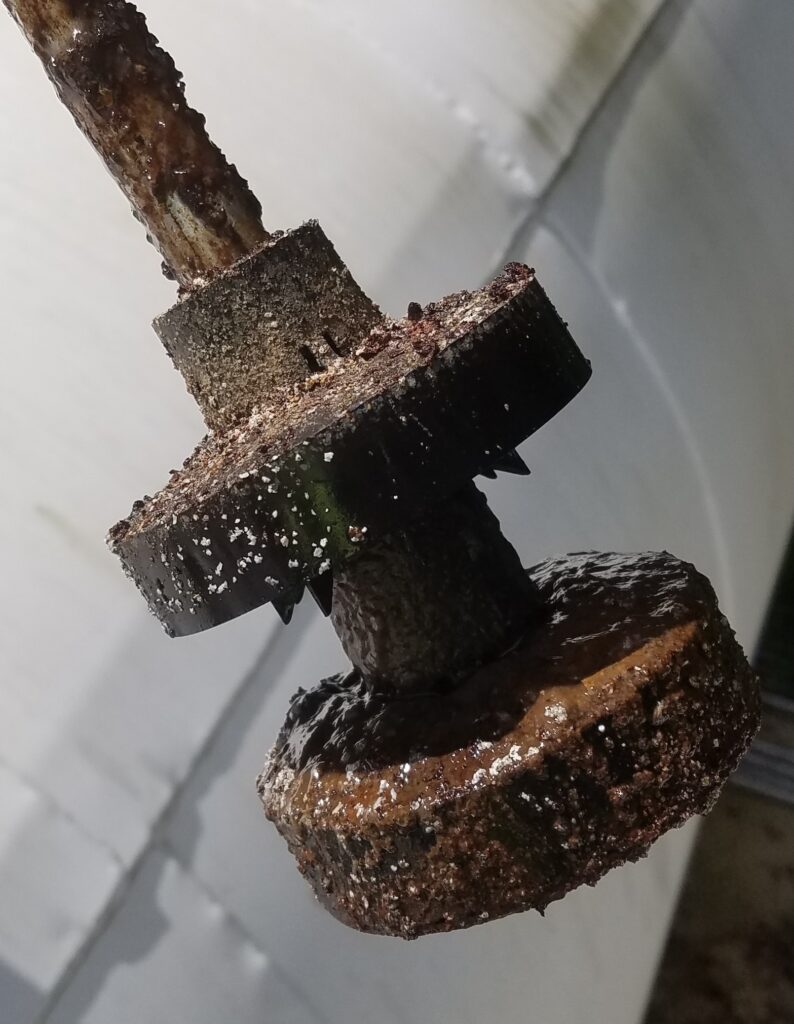

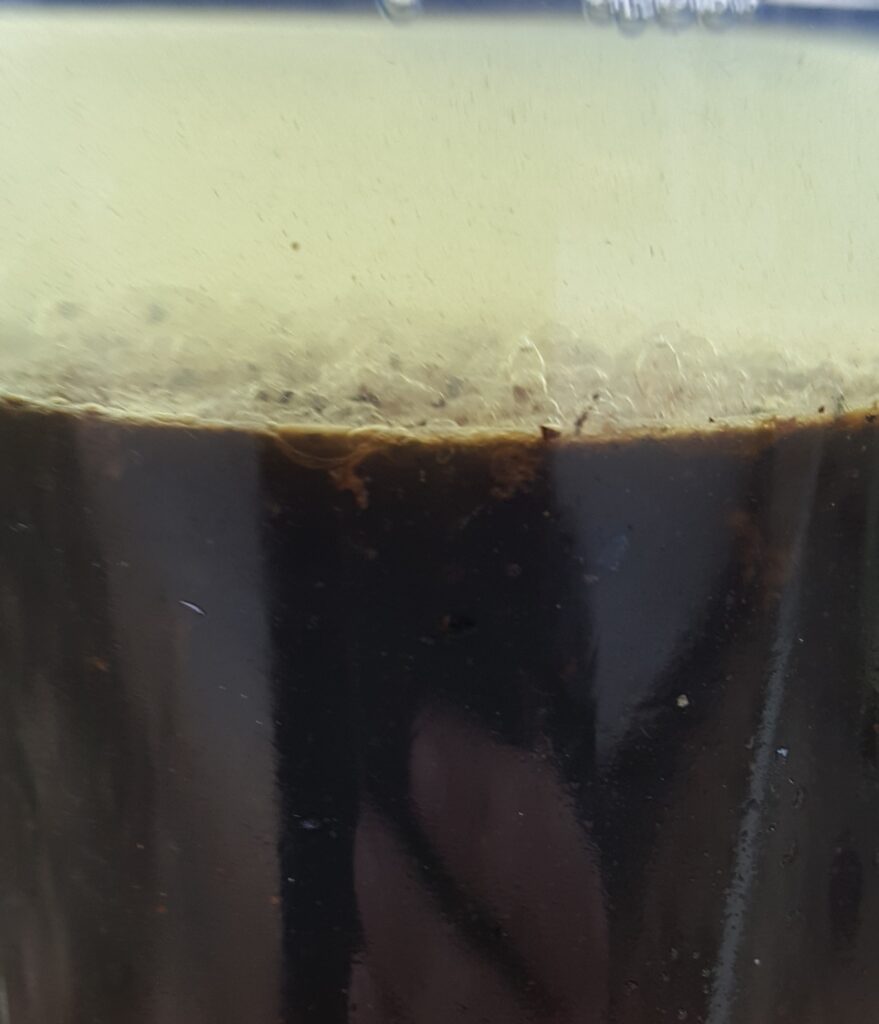

One of the most damaging effects of biofilms is microbial influenced corrosion (MIC). Microorganisms modify the tank environment, secreting acids and producing electrochemically corrosive conditions, resulting in metal pitting and system failure. The pictures below show biofilm, MIC and biomass removed from fuel systems that had biofilm problems.

Some promote filtration and cleaning alone to disinfect a fuel system, claiming biocides are not necessary. The only way to kill microbial contamination is to use a quality biocide, like Biobor JF. Once the system is cleaned and treated, periodic Biobor JF treatments help to maintain the level of cleanliness and reduce the chances of future biofilm formation. You can bet that contamination issues are costing money – studies show upwards of 35% higher maintenance costs due to contaminated fuel. Regular Biobor JF treatments and water removal along with yearly tank cleaning offer the best solution.

Share the Post