Fuel biocides are chemical additives used to control and prevent microbial contamination in fuels. Microbes such as bacteria, fungi, and yeast can proliferate in fuel systems, particularly in stored or stagnant fuel, and cause various issues. They are specifically designed to inhibit the growth and activity of these microorganisms.

Biobor JF is designed to address microbial contamination in fuels. It is formulated to effectively kill or inhibit the growth of bacteria, fungi, and yeast that contaminate fuel systems. It targets and eliminates these microorganisms, preventing their proliferation and the associated problems they cause. It helps prevent the formation of biofilms in fuel systems that lead to clogged fuel filters, corrosion, and fuel flow issues. By inhibiting biofilm formation, Biobor JF helps maintain the cleanliness and efficiency of the fuel system. Unlike other biocides, Biobor JF is dual phase, working in both the fuel and water phase to effectively control microbial contamination throughout the fuel system. However, only Biobor JF offers additional benefits that other biocides do not.

Additional Benefits of Biobor JF

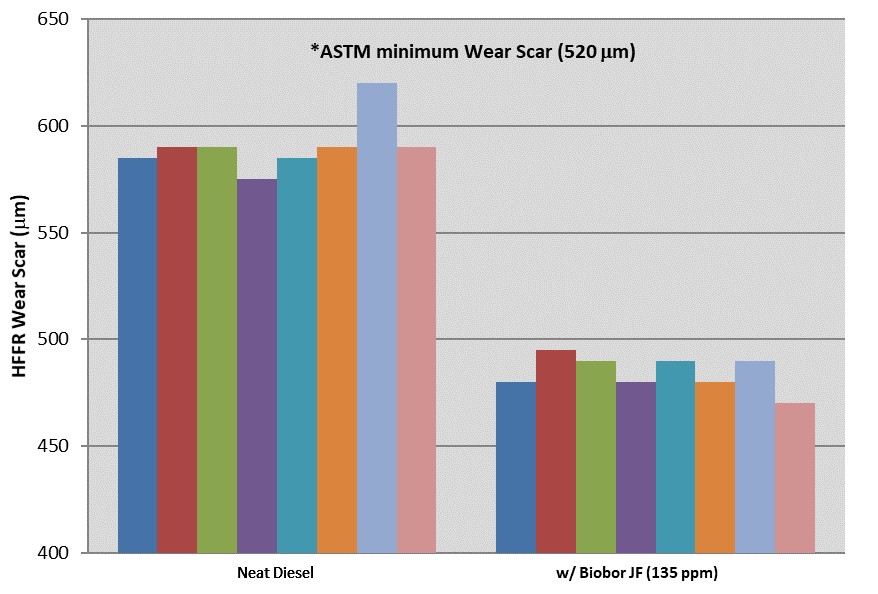

Biobor JF increases fuel lubricity. No other fuel biocide can make this claim. Only Biobor JF reduces engine wear scar by over 20%. In a year long field study, Biobor JF was found to reduce injector wear and substantially reduce injector tip deposits. Reducing engine wear and injector deposits contributed to much lower operating and maintenance costs.

Biobor JF reduces piston ring wear. In full scale laboratory tests, engines equipped with radioactive piston rings revealed over 50% reduction in wear to the piston rings. Similar results were found in the one year field study. Many fuel biocides contribute to corrosivity and can cause abnormal engine wear. Biobor JF does just the opposite. It reduces engine wear and facilitates lower operating costs as a result.

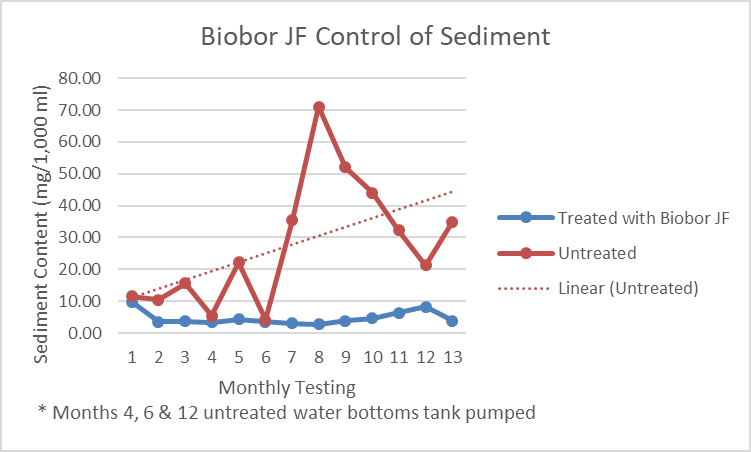

Biobor JF reduces sludge, sediment and water. Multiple studies have been performed on Biobor JF to determine its ability to reduce sludge, sediment and water. One field study was performed on two – 1,000,000 gallon storage tanks supplied with the same diesel fuel. In the one year study, one tank was treated with Biobor JF and another left untreated. Sediment and sludge was determined from both tanks to be similar. Each tank was tested bi-weekly during the test program. Microbes proliferated in the untreated tank and the sedimentary products increased accordingly. In the graph below it is easy to see the stark comparison of the two tanks. Most notable is the housekeeping efforts – pumpin the untreated water bottom periodically – offered only temporary relief to the fuel sediment and sludge problem. Only with the use of Biobor JF was the sediment problem minimized to near zero levels.

In another study, Biobor®JF was used to treat 1,395,000 gallons of B20 biodiesel for 11-months. The test was conducted on three ferry vessels. During the program, prior to testing, the biodiesel used clogged the fuel purifiers. Heavy contamination levels were found after thorough testing. Initial treatments in each tank of 270ppmw were followed by 135ppmw in all subsequent fuel deliveries. The microbial contamination responded well to the biocide treatment as visible in the before and after treatment photos of an oil purifier below.

Biobor JF increases storage stability. Instability is an ongoing problem with diesel fuel. Manufacturers typically give diesel fuel a 6 month shelf-life. Any long-term storage event is often accompanied by plugged filters, injector and fuel pump failures and the formation of insoluble gums. Storage stability testing completed on untreated and Biobor JF treated fuel was completed. The testing consisted of storing samples of the two fuels with metallic iron and copper catalyst coils at 110°F for four months. The fuels were tested each month for insoluble gum and color changes. Four months’ storage under these severe conditions is equivalent to over one year’s storage under normal field conditions. In each of the monthly tests, the untreated fuel failed to meet the minimum specification. The fuel treated with Biobor JF passed each month, stabilizing the fuel for over one year under extreme conditions resulting in a reduction of over 40% of insoluble gum formation over long storage periods.

Biobor JF is not just a fuel biocide. It adds lubricity, reducing engine wear and costs associated with today’s dry fuels. It stabilizes fuel for long-term storage. It reduces sediments, sludge and water, helping to reduce the number of filter changes. It is soluble in both fuel and water so it will protect your entire fuel system. Using Biobor JF has proven over and over it will save you money, reduce downtime and preserve your fuel. Buy yours today.

Follow BioborShare the Post

Pingback: Where Microbes Live – Biobor Fuel Additives