The video shows diesel fuel contamination in a flow stream taken during fuel polishing. Looks bad. Did you know the average retail fueling site pumps about 1.2 million gallons per year? In a years time, the tanks will accumulate approximately 90 pounds of particulate contamination in total. That is a lot of contamination. The same tank system will also accumulate water through condensation and other sources like leaks and delivery contamination. Add to these, microbial contamination and you have the perfect storm brewing inside your fuel system. Take a look at the photos below illustrating the issues just described.

From the video and these photos, it is easy to see the importance of tank cleaning or fuel polishing. Some ask, “What is the difference between tank cleaning and fuel polishing?” And, if I clean or polish, do I need to use biocides or additives?” This post will help answer these questions and more.

What is Tank Cleaning?

There are generally two broad categories of tank cleaning, manned entry and unmanned entry. Tank cleaning involves the removal of fuel usually with filtration before the tank is chemically cleaned. The cleaning is done using high pressure jets either by manned entry or unmanned processes. Typically, retail and commercial tanks are cleaned using a nozzle jet that is extended into the tank while a water or water-chemical solution is jetted onto the surface of the interior tank to remove sludge and contamination. The contaminants are generally vacuumed out, leaving a clean tank ready for the filtered fuel to be dropped back in.

What is Fuel Polishing?

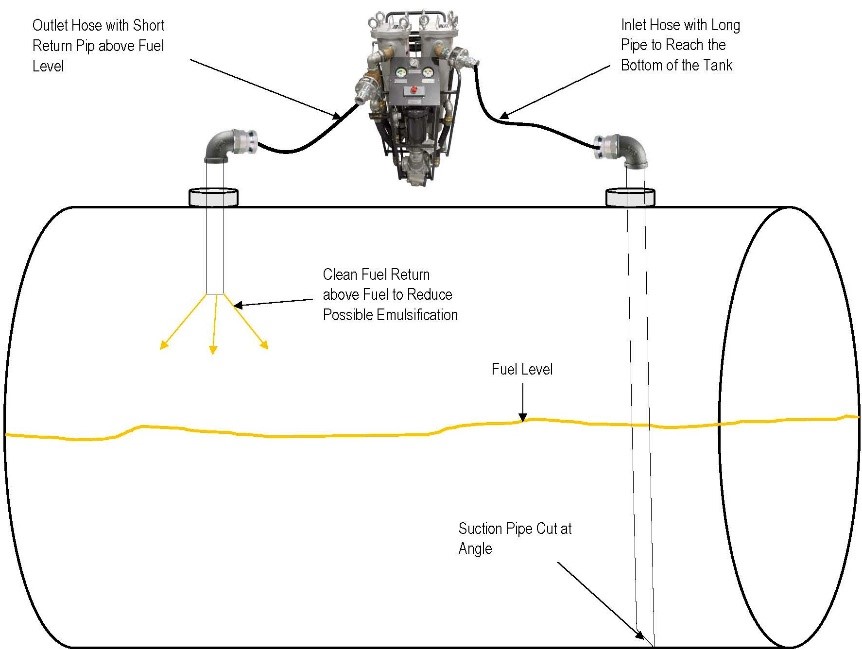

Fuel polishing is the most common service performed. It involves filtering the fuel through a kidney loop process. See the below illustration.

The fuel is pumped out of the tank through a filtration system and back into the tank. There are numerous variations including some that use hoses that run down the bottom of the tank to collect contaminants. Most filtration systems include some method of removing water during the filtration process. The contaminants are filtered out and the clean fuel is cycled back into the tank until there is no more contamination found and the fuel is bright and clean. The same kind of filtration is also used during tank cleaning to remove and filter the fuel prior to returning it to the cleaned tank.

The question remains, “Does tank cleaning or fuel polishing kill and remove microbes and can it remediate fuel deficiencies?” The answer is no. While tank cleaning and fuel polishing are an important part of fuel quality management, the only way to kill microbial contamination is with a fuel biocide. It is also important to remember that the tank is not the only part of the fuel system with potential contamination. It is not uncommon to find microbial contamination in lines and dispensers. Most filtration systems will filter down to no smaller than 5 microns. Microbes are so small, they flow right through the filters, entering back into the fuel.

The optimal approach is to treat the fuel with a shock dose of Biobor JF microbicide at least 24 hours before cleaning or polishing and agitate the fuel to provide a faster application throughout the fuel. This can be accomplished by adding the biocide just prior to a fuel drop. Allowing for an adequate soak time prior to cleaning provides a better result. Biobor JF will kill the microbes that then flocculate (form into small clumps or masses) making them easy to filter out during the cleaning process. If tank cleaning is performed using water, it is best to add a final maintenance dose of Biobor JF when the fuel is pumped back into the tank because there is often residual water left over from the cleaning process. This will help ensure microbial reinfection does not occur.

What about fuel deficiencies? Fuel testing can confirm any deficiencies and fuel additives can help with that. The most critical fuel systems are those supplying fuel to generators. Even with cleaning and the use of biocides, additives are necessary to stabilize the fuel and reduce the effects of oxidization, aging, water exposure and temperature change. If you haven’t already, check out our prior post for more detail on fuel additives.

One additional note is necessary about bolt on filtration systems. Common among generator fuel systems, bolt on or integrated filtration systems also lack the ability to kill microbes or remediate fuel. Biocides and fuel additives remain the most relevant way to kill microbes and keep fuel from going bad.

A good fuel quality management program includes all of the above. Cleaning, polishing, biocides and additives. In the next post, we will wrap up our series with Hammonds Fuel Additives fuel quality management program – Test, Treat Protect.

Share the Post

I have been making and using biodiesel for about 8 years and I have a 110 gallon auxiliary tank on the back of my flatbed F-450. This is the 3rd time I have needed to clean out the tank because I haven’t treated the biodiesel or the tank. Question: The inside of tank has a film of rust, and bottom looks black. How can I clean tank out properly and stop this from happening again?

Thank you

Leo

Sounds like you tank needs to be physically cleaned. I would treat the fuel with a shock dose of Biobor JF; allow an adequate soak time; filter the fuel out of the system; physically clean the tank, removing the contamination; refilter the fuel back into the tank and shock dose one additional time with Biobor JF. In the future, I would regularly treat the fuel with Biobor JF to keep microbial growth from getting back into the fuel. Biofuel is a good food source for microbes and microbes are always present in the atmosphere. To keep recontamination from happening, a regular treatment is recommended.

Thanks a lot. If there’s no your article, I won’t see the importance of cleaning a fuel tank. This is a useful article. Hope you write more.

Thanks so much. Subscribe to our blog and be the first see new articles. We usually post weekly. Have a great holiday.