The Ideal Fuel Biocide

Microbial contamination through the supply chain has been well documented over the years. All fuel is susceptible to microbial contamination and you would be hard pressed to find a fuel system that did not have some level of contamination. Systems that are not intentionally managed for fuel quality and are contaminated will have ongoing issues, including but not limited to poor fuel quality, line and tank fouling, plugged filters, damaged pumping equipment and damaged engines. The single most efficient way to alleviate these problems is to regularly apply a fuel biocide. The question arises, “Which biocide should I use?”

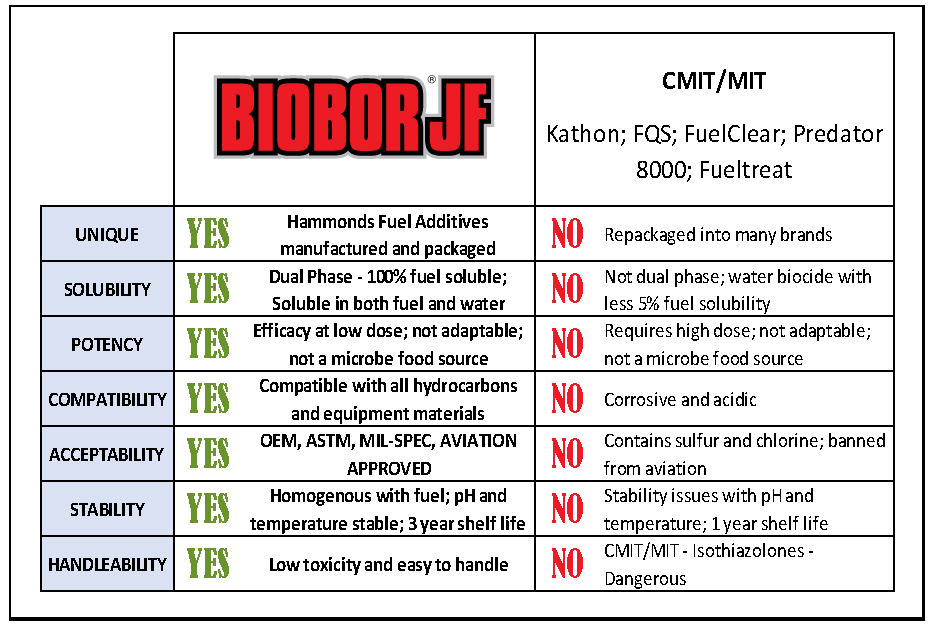

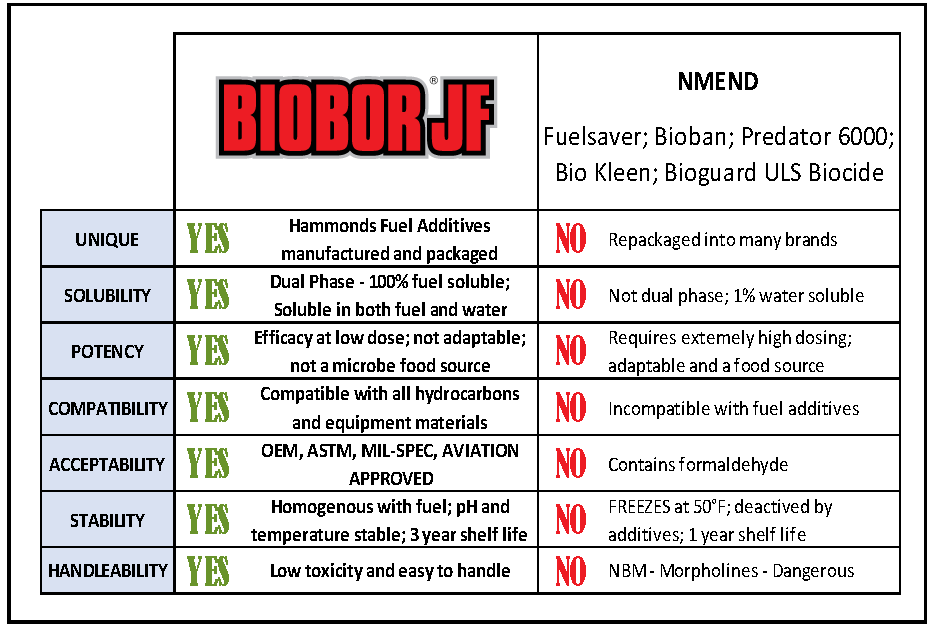

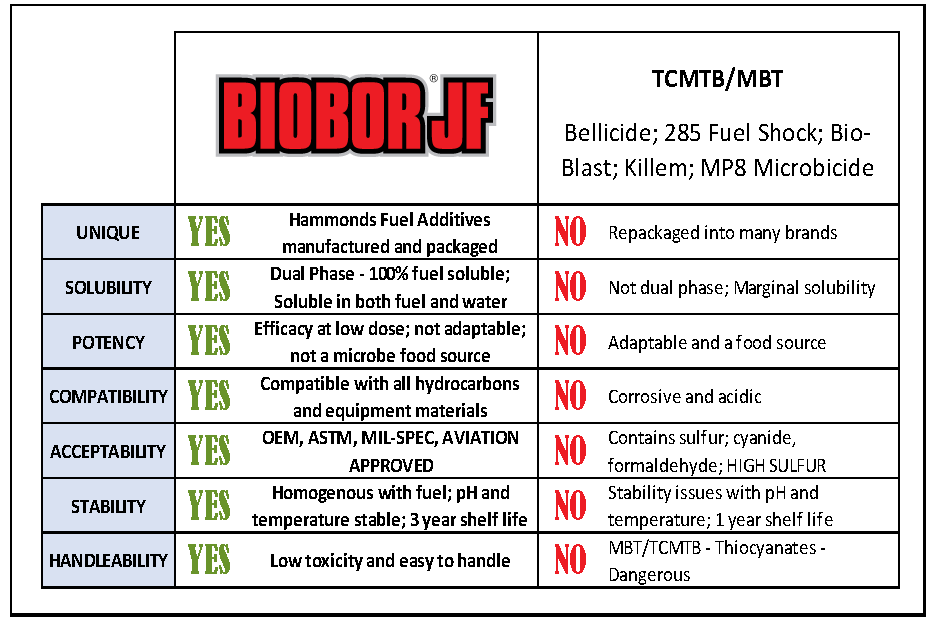

Over the last several posts, we have analyzed popular fuel biocides. We will now recap the analysis with a comparison of each to Biobor JF. By the end of the post, the answer to the question, “Which biocide should I use?” will be answered. As with the other posts, we will briefly break down the analysis using the same 6 attributes.

6 Attributes of an Ideal Fuel Biocide

- Solubility

- Potency

- Compatibility

- Acceptability

- Stability

- Handleability

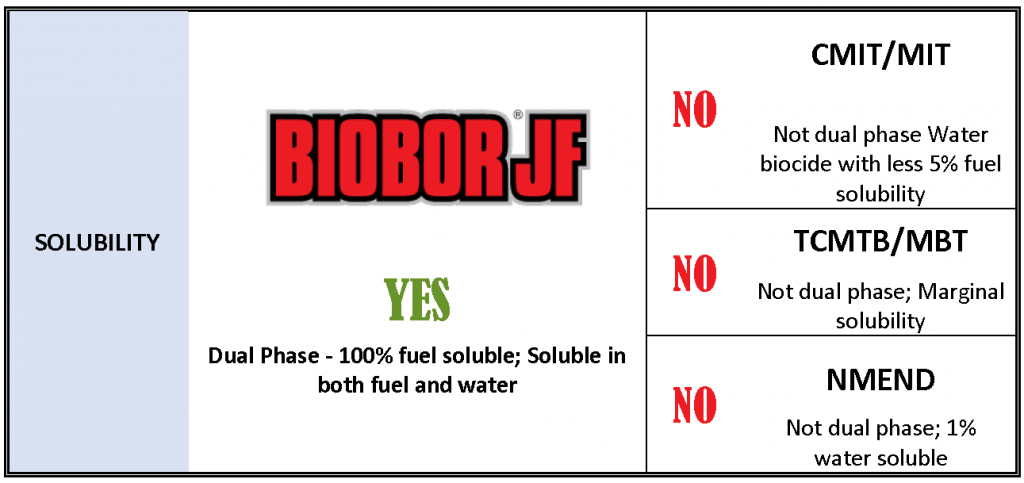

Solubility

Of all the biocides analyzed, Biobor JF has the ideal solubility. Biocides containing TCMTB/MBT, CMIT/MIT or NMEND all had serious solubility issues. To summarize, two were not soluble or had marginal solubility in fuel and one only had 1% water solubility. In order for a biocide to preserve the fuel and protect the system, it must be dual phase. That is, it must be able to solubilize in fuel, remaining in the fuel until it comes in contact with water, then partition properly into any water present to make an effective kill in both phases. Anything less will not provide adequate fuel and system protection. That is why Biobor JF is perfect for the job. Field and laboratory studies confirm Biobor JF is dual phase. It is miscible in fuel (100% soluble) and offers more than 50% water solubility. It stays in the fuel until it comes in contact with water. Only then does it partition into the water, optimally designed to kill microbial contaminants in both phases.

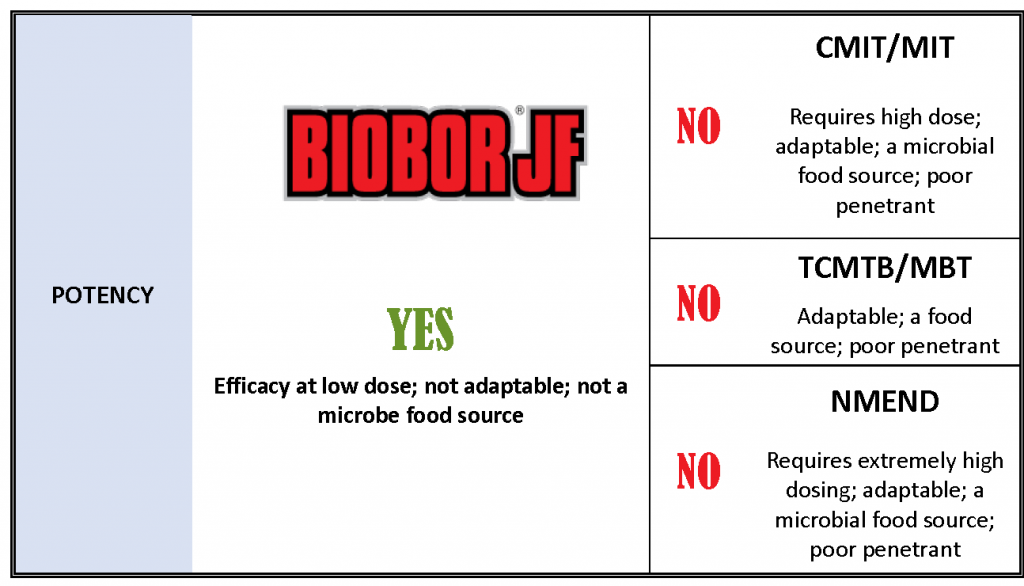

Potency

Biobor JF is also the best choice when compared to others for potency. Microbial species were shown to adapt to or became resistant to TCMTB/MBT, CMIT/MIT and NMEND. Both TCMTB/MBT and CMIT/MIT act as a food source for microbes. NMEND and CMIT/MIT required extremely high dose treatments to be effective. NMEND required 10 times more biocide than Biobor JF, so much so it would be more chemical needed to kill the microbes than regulations allow. All three of the competitor biocides are poor penetrants compared to Biobor JF. When biomass accumulates in a fuel system they are not efficient at breaking though the microbial buildup. Based on competitor treatment doses required to actually make an effective kill, the cost to treat with all three was considerably higher than Biobor at just 270 ppm.

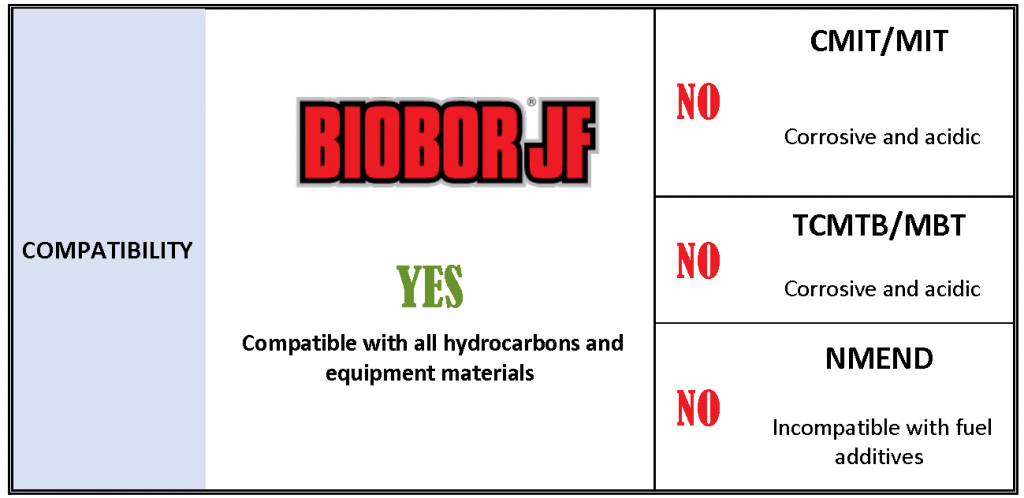

Compatibility

The ideal fuel biocide should be compatible with both fuel and equipment. NMEND had fuel compatibility issues with diesel fuel stabilizer additives commonly used. The others had equipment compatibility issues, some with major system materials like carbon steel and stainless steel, causing corrosion and potential serious system issues. Biobor JF has neither incompatibility with fuel or fuel systems. It is an anti-corrosive biocide, adding lubricity to fuel and protecting fuel systems.

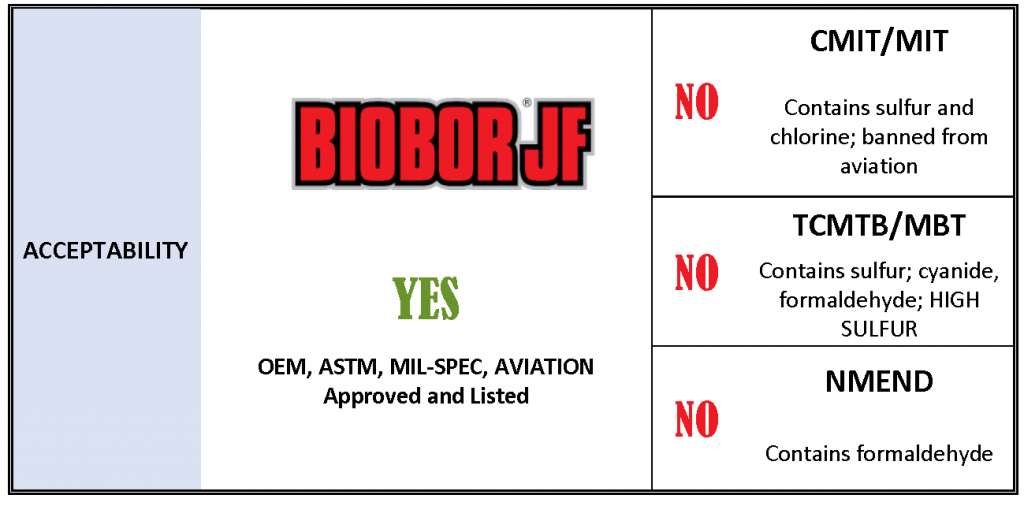

Acceptability

Biobor JF is the most acceptable fuel biocide on the market. It is OEM approved, Mil-Spec approved, ASTM listed and it is the only aviation approved fuel biocide available today. No other biocide on the market has accumulated the list of approvals Biobor JF has over its 57 year history. It was the first biocide specifically designed for fuel, unlike most other biocides that were designed for water applications and later marketed as fuel biocide.

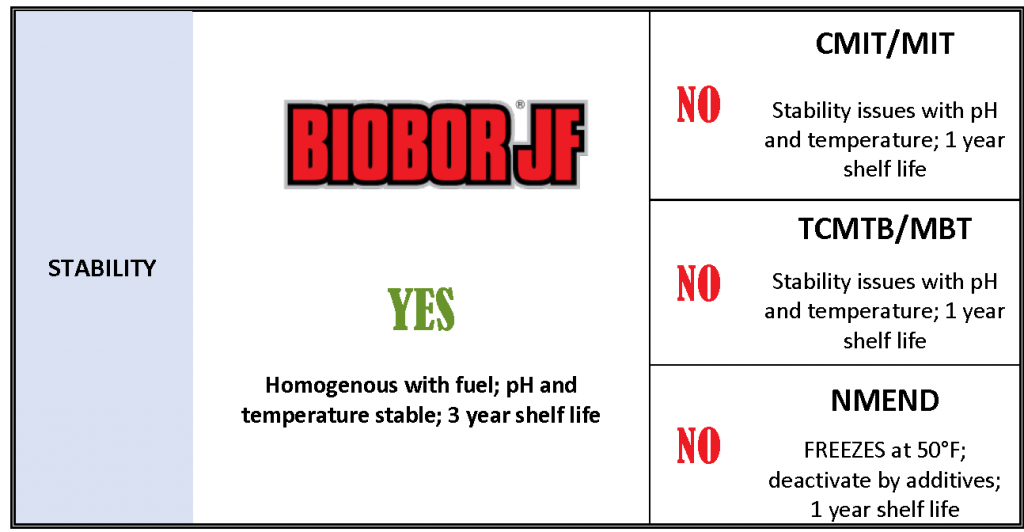

Stability

The importance of chemical stability cannot be overstated. Compared to the others, Biobor JF is the most stable fuel biocide. The rest have pH and temperature instabilities. Extra caution, extra effort and more issues to worry about while storing and using a biocide. Unlike these, Biobor JF is not affected by pH or the extremes of temperature, either hot or cold. Both TCMTB/MBT and CMIT/MIT react to and are deactivated by moderately high temperatures often associated with storing a product. NMEND freezes at 50° F and it is deactivated by common additives in diesel fuel. There is no comparison when you look at the issues with the others. The shelf life of all three competitor products is a maximum of 1 year. Biobor JF has a three year shelf life. Studies show it to be stable even longer.

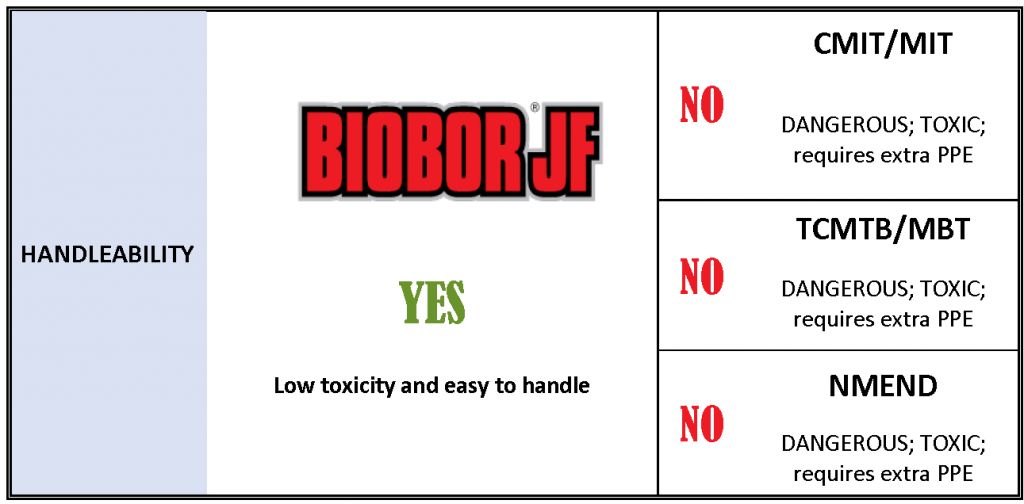

Handleability

Biocides are potentially dangerous and difficult to handle. Toxicity is a problem with all of the biocides analyzed, some worse than others. Toxicity, corrosivity and acidity are all concerns to those handling the product. Unlike the others, Biobor JF has been noted by the EPA as having low toxicity. Testing proves it to be non-corrosive. The same handling precautions used for fuel can be used for Biobor JF. No special personal protection equipment. Not true of the others. The competitor products all have additional handling instructions, some even requiring mask and respirator. Suit up if you plan to use the others and be aware of the potential personal exposure to chemicals with them.

Biobor JF is the Ideal Fuel Biocide

Compared side-by-side, there is no better fuel biocide on the market than Biobor JF. Still deciding? Scroll through the comparison charts below. There really is only one answer – Biobor JF!

Follow BioborShare the Post

Pingback: The Biobor Advantage – Biobor Fuel Additives