Thiocyanate Biocides

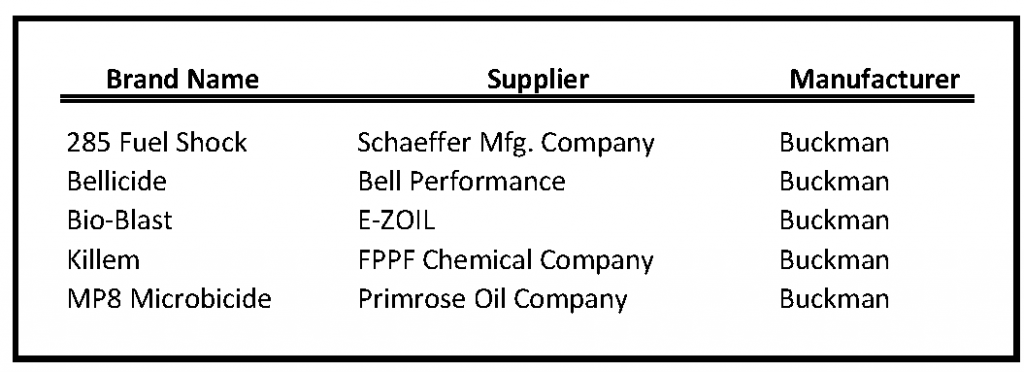

The last several posts delved into fuel quality management specific to certain industries. In each one the conclusion was the same. Use a quality biocide – specifically Biobor JF – at least quarterly to effectively eliminate microbial influenced fuel quality issues. To continue this conversation over the next several posts we will examine competitor products and compare them against Biobor JF. This post starts with TCMTB/MBT biocides also referred to as Thiocyanates or Thiazole. Buckman Laboratories invented the product and is the primary manufacturer that is currently relabeled under many different brand names. Most of the repackaged products are manufactured by Buckman. There are very few actual manufacturers of the biocide, most brands are private label packed by Buckman. For the purpose of this post, we will refer to it by its acronyms TCMTB/MBT. The chart below shows some of the more common product labels among a host of more than 200 others.

On June 3, 2021 our post The Ideal Fuel Biocide laid out 6 attributes to describe why Biobor JF is just that – THE IDEAL FUEL BIOCIDE. We will use these same 6 attributes to investigate the competitor product.

6 Attributes of an Ideal Fuel Biocide

- Solubility

- Potency

- Compatibility

- Acceptability

- Stability

- Handleability

SOLUBILITY

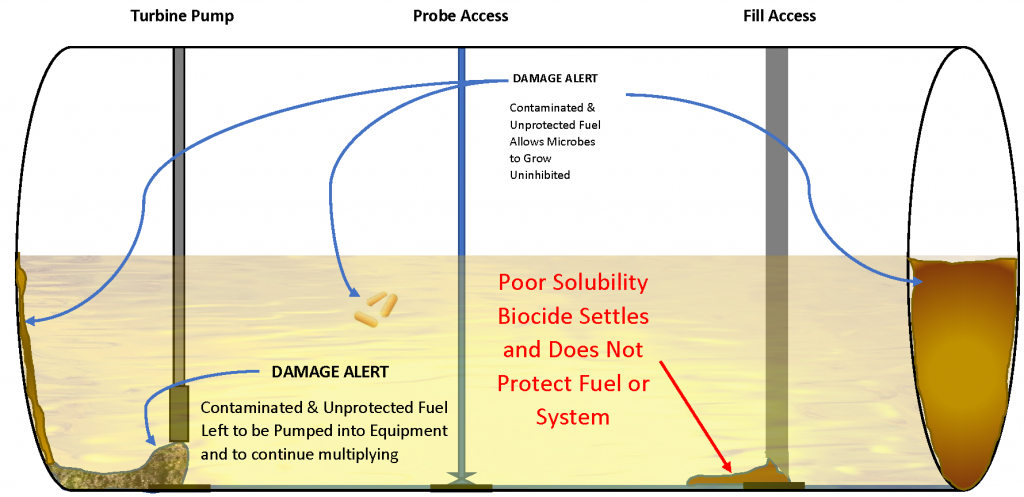

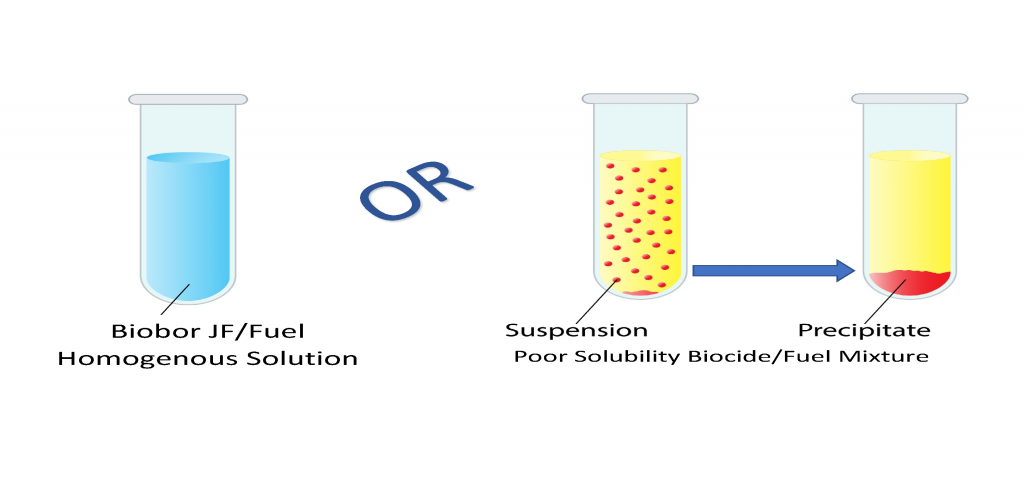

How important is the solubility of a fuel biocide? Fuel systems contain both fuel and some level of water. While the water may be undetectable with the eyes, it is always present. A quality biocide must be readily soluble in fuel and able to partition into water when it is found. In order for a biocide to effectively kill microbial growth throughout a fuel system, it must be fuel soluble. Biobor JF is miscible (100% soluble) in fuel and has good water solubility. When present, it will partition into the water and effectively kill any microbes. In contrast, TCMTB/MBT is practically insoluble in fuel. Not surprising since it was developed as a water systems and cooling tower biocide. It was never designed for fuel. This presents a serious problem because it may not adequately decontaminate or protect a fuel system. The diagram below illustrates the problem with any poorly soluble biocide like TCMTB/MBT.

Pour it in and that is where it stays. The carrier solvent (86% of the product) used in TCMTB/MBT is DiEGME. It is a corrosive and aggressive solvent often called apple jelly because it tends to settle out and looks a lot like apple jelly when it is found in the fuel tank. Even if you blend it in, it will precipitate along with the active biocide ingredients. There is no comparison between Biobor JF and TCMTB/MBT. Studies show Biobor JF will dissolve into the fuel with little to no blending. In contrast a TCMTB/MBT biocide might initially mix but will end up precipitating and will not protect the fuel or system. A product that rapidly settles to the bottom of the tank will never reach the microbial biofilm communities like those illustrated above or provide comprehensive protection.

POTENCY

There is more to biocide efficacy. Efficacy testing alone should never be the only qualifier. It is more a question of potency. How potent is TCMTB/MBT? Does the biocide adapt to microbial species; is it a nutrient source for some; or does it effectively control biomass? These are all valid questions associated with the efficacy of a biocide. As we have already seen with solubility, TCMTB/MBT is limited in its ability to kill microbial contamination because it may not solubilize and reach all the fuel and all areas of the fuel system. This is just one of several serious problems identified with using the biocide.

There are numerous cases of microbes adapting to TCMTB/MBT. What does that mean? When a microbe adapts to a biocide, the biocide is no longer capable of killing the microbe. In fact, there are numerous cases on record of common bacteria that metabolize (consume) this biocide as a food source. In order for any biocide to be potent, it cannot be used as a nutrient source or be resistant. Biocide resistance or adaptation is a major problem associated with TCMTB/MBT. Microbes adapt and become resistant to the biocide, allowing them to grow and flourish in the fuel system. This biocide lacks potency because it is known to be adaptable and is a food source for a host of microbial species commonly found in fuel systems.

TCMTB/MBT is also a poor penetrant. It is not capable of penetrating microbial biomass making it a poor solution for long-term storage. Microbial biomass buildup on the bottom and along the sides of fuel tanks are common. Generator systems, agricultural tanks or equipment used seasonally are especially vulnerable if left unprotected. A biocide that cannot penetrate biomass where microbes live cannot be effective at protecting a fuel system.

In contrast, Biobor JF has never been shown to be adaptable or found to be a nutrient source. Studies demonstrate it controls biomass in the worst of situations and over long-term storage periods. Potency is more than basic efficacy. Using an inadequate biocide like TCMTB/MBT will create more problems than it solves.

COMPATIBILITY

Another significant attribute of a quality biocide is its compatibility with the fuel and fuel system components. Many biocides are highly corrosive and lack solubility resulting in a product that damages the fuel system. Some biocides actually react with component materials. TCMTB/MBT is one such biocide. It reacts with iron. That means if you have lines, tanks or pumping components made from steel, TCMTB/MBT will cause corrosive pitting and potentially failure over time. Laboratory testing confirms the biocide caused considerable pitting on carbon steel, not a good choice for fuel systems.

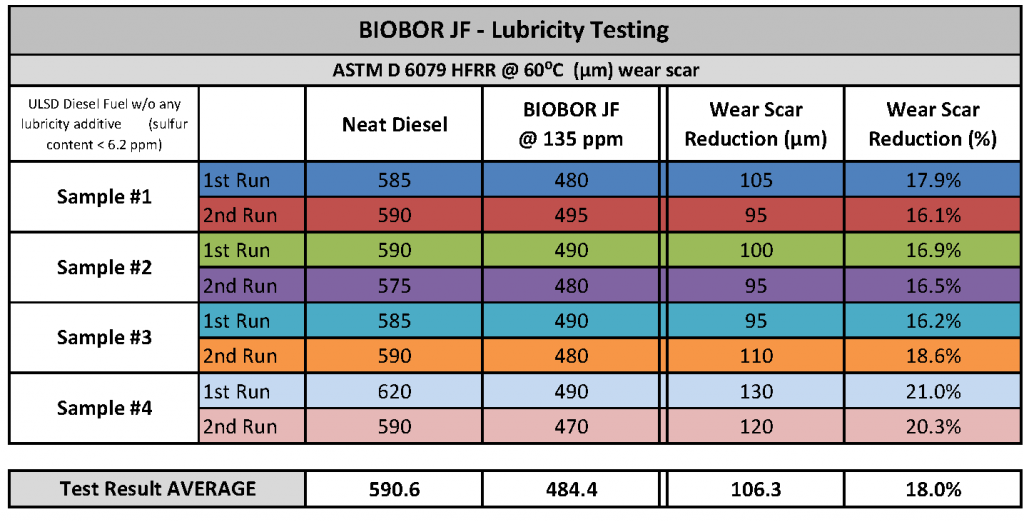

In contrast, the results of NACE laboratory experiments on Biobor JF conclude that it is a non-corrosive material. In fact, it is a lubricity additive. Tests show that it reduces engine wear scar by around 20%, a significant factor given the alternative. Why use a biocide that is harmful to the fuel system when one is available that will effectively kill microbial contaminants as well as reduce corrosion and equipment wear.

ACCEPTABILITY

Biobor JF is OEM approved, ASTM listed, aviation approved, Mil-Spec approved, used globally and does not contain concerning chemistries. In contrast TCMTB/MBT is not OEM approved, not ASTM listed, not aviation approved, not Mil-Spec approved, cannot be used globally and DOES CONTAIN CONCERNING CHEMISTRIES. Let’s break this down.

First and foremost, TCMTB/MBT does not have global approval. In fact, many of the repackaged brands like Bellicide are not approved for use in all 50 states. This biocide reacts in the fuel system resulting in the release of cyanide, formaldehyde and peroxide. These are all reaction products of concern to numerous agencies. According to the manufacturer, it hydrolyzes in water to form hydrogen sulfide and formaldehyde, both dangerous and damaging. We will talk more about the toxicity and exposure issues later.

One of the biggest problems with using this product in fuel is that it does comply with the EPA (and other agencies) ultra-low sulfur diesel fuel requirements. The manufacturer places the warning on its label saying:

“This diesel fuel additive does not comply with federal ultra-low sulfur content requirements for use in model year 2007 and newer diesel motor vehicles or model year 2011 and newer diesel nonroad equipment engines.”

Manufacturer Warning

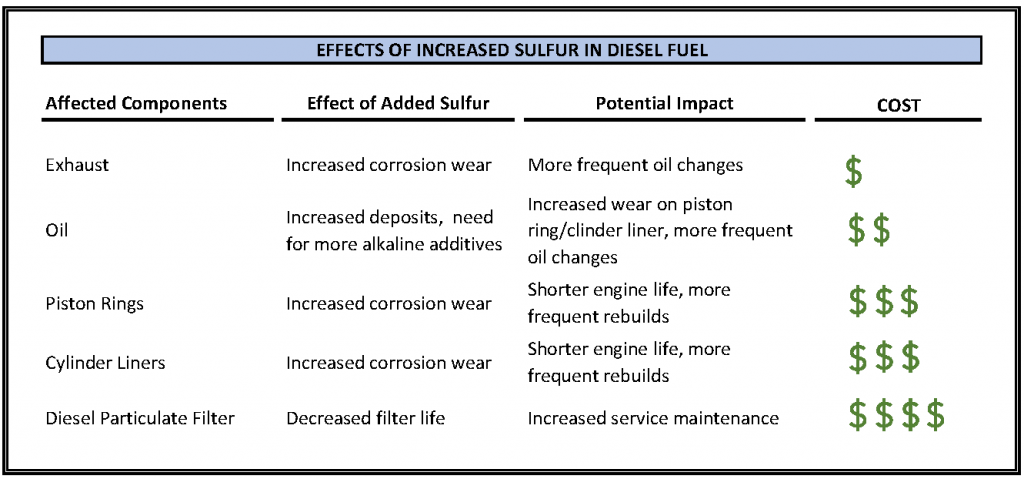

When tested, it was found that TCMTB/MBT contains around 14,000 ppm sulfur. This is enough to make fuel non-compliant and out of spec. Additionally, high sulfur damages engine components as illustrated in the graph below.

Biobor JF does not contain sulfur. An acceptable biocide is one that does not contain questionable chemistries. The EPA notes in its assessment of Biobor JF that it “posed no risks of concern when used according to EPA-approved product labeling.” The same is not true of TCMTB/MBT.

STABILITY

A quality biocide should be able to work in a wide range of conditions. Just how stable is TCMTB/MBT? Does it work in a wide range of conditions or is it limited? Two conditions that affect biocides are pH and temperature. Fuel systems almost always contain some level of contamination, most common being a water layer at the bottom. Most bottom water environments have a pH range between 6.8 and 8.5. Studies show that TCMTB/MBT quickly hydrolyzes and deactivates in a pH greater than 7.5. That is over half the pH range found in the average fuel system. That means the biocide will deactivate in a large portion of fuel systems before it can ever accomplish its task of killing microbes. Additionally, if long-term storage is your goal, count TCMTB/MBT out.

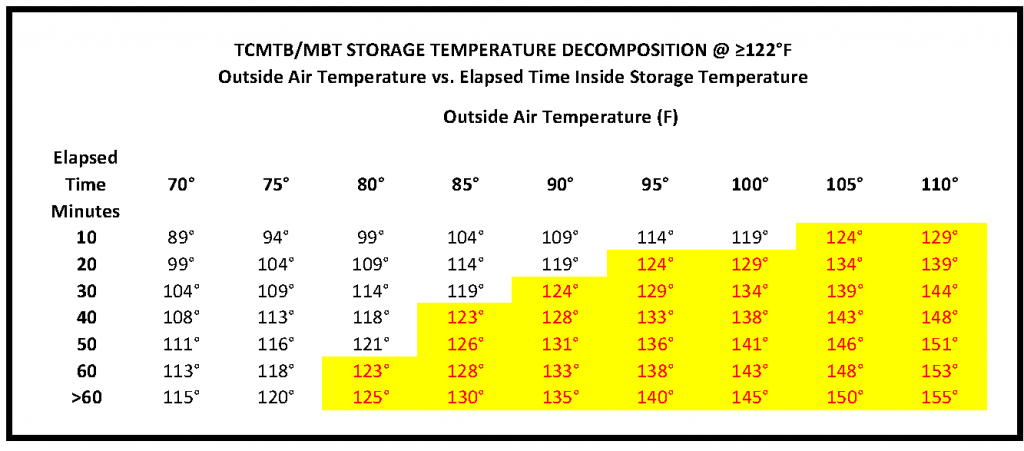

What about temperature instability? According to the manufacturer, the biocide decomposes at 122°F, forming hydrogen cyanide, sulfur dioxide and cyanide salts – a dangerous combination. How would it ever get that hot? Consider storage temperatures. The chart below shows how outside air temperatures relate to inside storage temperatures. Using the chart, if you store a bottle of Bellicide or any other TCMTB/MBT biocide in your service vehicle or in a storage shed with an outside air temperature of 80°F, it only takes an hour before the inside temperature reaches 123°F, enough to deactivate the biocide. On hot days, the inside temperature could rise well over 140°F, enough to deactivate it and cause the biocide to react violently, releasing deadly gases. Biobor JF is both pH and temperature stable. It is not affected by either even when field conditions are not ideal.

HANDLEABILITY

Just how easy is TCMTB/MBT to handle? Is it toxic? Do you need special personal protection equipment (PPE) to handle it? The manufacturer labels it toxic. Numerous studies show it to be potentially life-threatening from inhalation and capable of causing multi-organ failure. It is also a confirmed skin sensitizer. It contains 95% volatile organic compounds (VOCs). That is significant. According to the EPA, “Volatile organic compounds (VOCs) are emitted as gases from certain solids or liquids. VOCs include a variety of chemicals, some of which may have short- and long-term adverse health effects.” TCMTB/MBT is one such chemical. The EPA classifies it as “highly toxic” through inhalation and a “dermal sensitizer.” The product label requires considerable PPE advising:

“Wear goggles or face shield. Wear coveralls over long-sleeved shirt and long pants; socks and chemical resistant footwear; chemical-resistant gloves such as barrier laminate, butyl rubber, nitrile rubber, neoprene rubber, polyvinyl chloride or Viton; and respirator with an organic vapor removing cartridge with a prefilter approved for pesticides (MSHA/NIOSH approval number prefix TC-23C); or a canister approved for pesticides (MSHA/NIOSH approval number prefix TC-14G); or a NIOSH approved respirator with an organic vapor (OV) cartridge or canister with any R, P, or HE prefilter.”

Product Label Warning

This is no short list of what is required to use the product. Handleability is a major factor to consider when using a biocide. The more toxic a product is, the more complicated and costlier it is to use. Because Biobor JF is of low toxicity, it does not require the long list of PPE. The same PPE used to handle petroleum products is all that is required. No special PPE to handle Biobor JF. Microbes are almost certainly present in your fuel system. The effective use of a biocide is the solution. The challenge is finding the right one to use – the ideal biocide. It is easy to see from this analysis that TCMTB/MBT including the numerous branded products – Bell Performance’s Bellicide, Schaeffer’s 285 Fuel Shock as well as others – are not the answer. They offer poor solubility and inadequate potency. They are not fully compatible with fuel or system components. They are not acceptable products, containing chemistries of question. They are unstable and highly toxic to use. There really is only one ideal fuel biocide – Biobor JF.

Follow BioborShare the Post