What is the shelf life of diesel fuel? So the answer may not be as simple as one would think. According to most refiners, diesel has an average shelf life of 12 months if stored at a temperature below 20°C (68°F). That may be realistic for underground storage tanks, but not for aboveground storage facilities. If temperatures reach above 30°C (86°F), shelf life is 6-12 months at best. As the temperatures rise, self life goes down. Temperature is not the only variable that affects the shelf life of diesel fuel.

Four variables that affect the shelf life of diesel fuel

- High temperatures

- Water contamination

- Particulate contamination

- Fuel composition

We have already discussed temperature. The next variable, water is the most serious. Water allows for the growth of bacteria and fungus. Microbial contaminants feed off of the diesel and produce organic acids that destabilizes the fuel. Accelerated aging is a direct result of microbial contamination. Water management practices should be in place to limit water exposure, realizing that there will always be some level of water present in the fuel.

Particulate contamination is another problem. Sand, dirt and rust are common contaminants found in fuel system. These all work to destabilize the fuel and cause reduced life. As a tank system breaths, contaminants are carried into the fuel and eventually settle to the bottom of the tank. Aging fuel systems also contribute to particulate contamination in the form of rust and water. If water is present, and it almost always is, particulates do additional harm by feeding microbial growth.

All diesel fuels are not the same. Fuel composition varies from supplier to supplier. Differences can be due to the original crude the fuel was refined from to the additive package added to the diesel fuel after refining. There are numerous ways fuel composition differs, all of which affect shelf life. So what can be done to prolong the shelf life of your diesel fuel?

Three steps to increase the shelf life of diesel fuel

- Establish a fuel quality management program

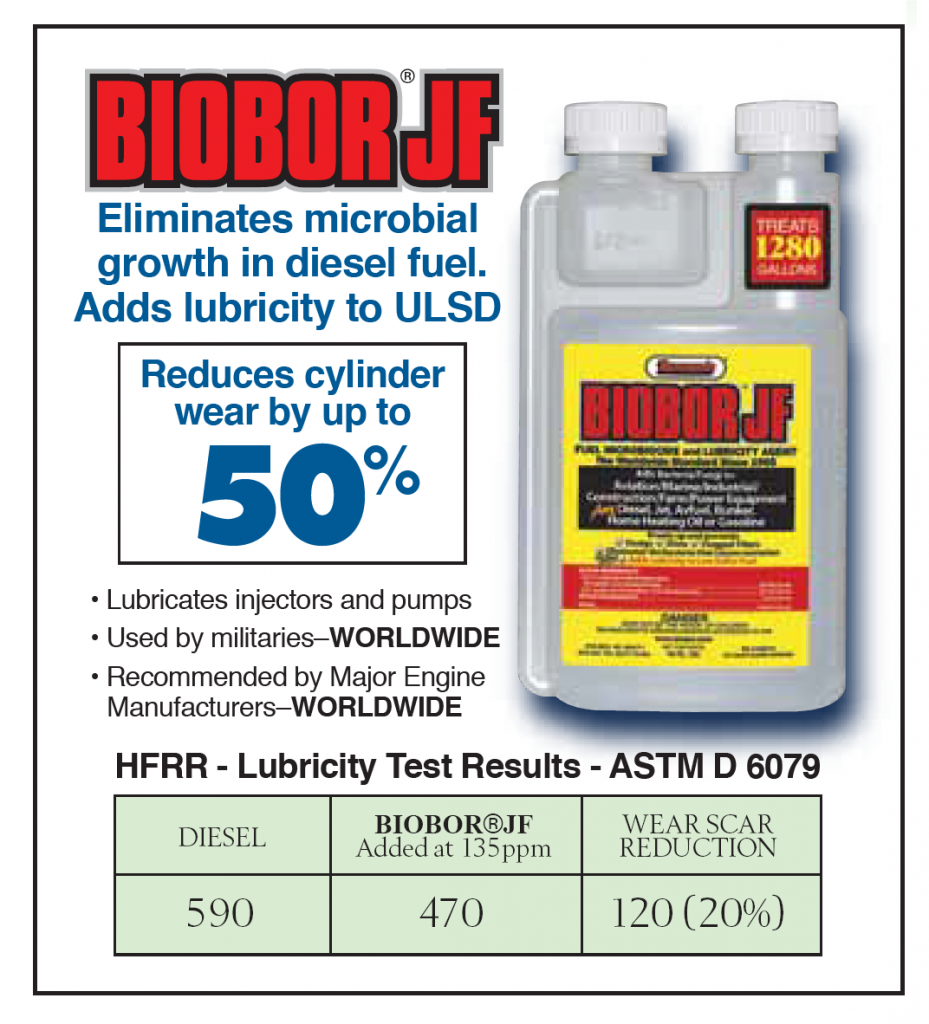

- Use Biobor JF fuel biocide to ensure the fuel is free of microbial growth

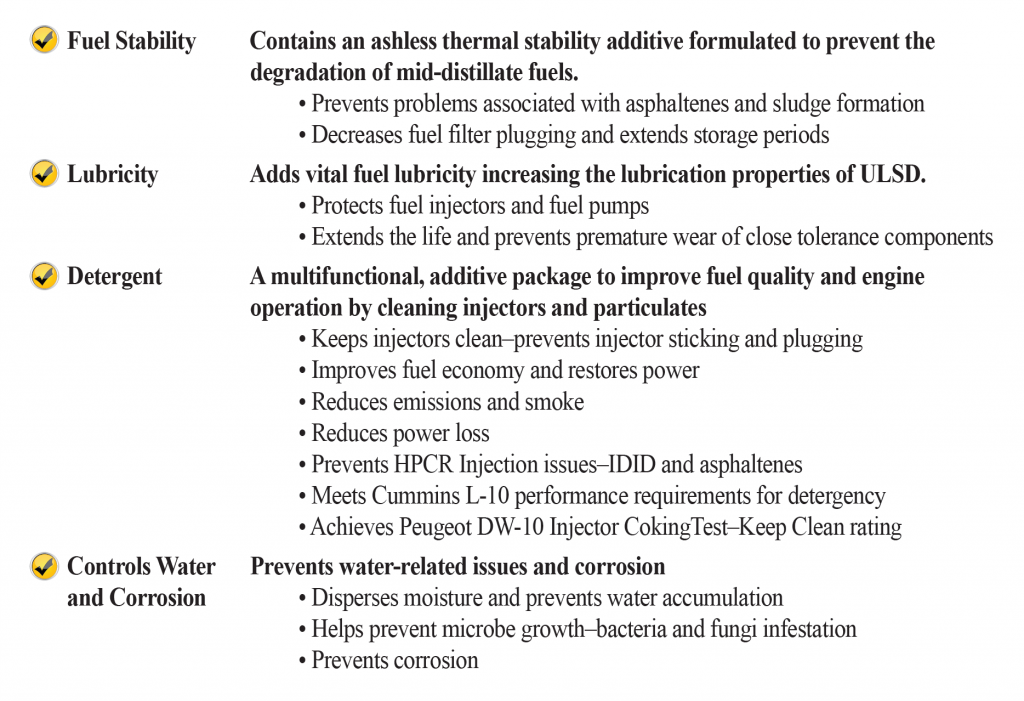

- Use Biobor DC to increase the life of your diesel fuel

There are no shortcuts to fuel quality management. Research shows that over 75% of tanks sampled are contaminated and contain fuel that does not meet current engine specifications. Sampling and testing the fuel is the ONLY way to determine what’s in your tank. If you find water or particulate contamination, remove it immediately. Test the fuel for microbial contamination and for total fuel quality. Identify a course of action to treat the fuel.

Use Biobor JF fuel biocide to ensure no hidden microbial issues will create a problem during long term storage. Because fuel systems often harbor issues outside of reach during sampling and inspections, use Biobor JF to preserve the fuel, resulting in a longer shelf life.

Use Biobor DC to increase the shelf life of your diesel fuel. It contains an ashless thermal stability additive formulated to prevent degradation associated with the challenges of long term storage. Test, Treat and Protect your way to long term fuel storage using Biobor fuel additives. There is no better way to preserving your fuel and fuel system.

Follow BioborShare the Post

Where can I send samples for testing? How big sample is needed?