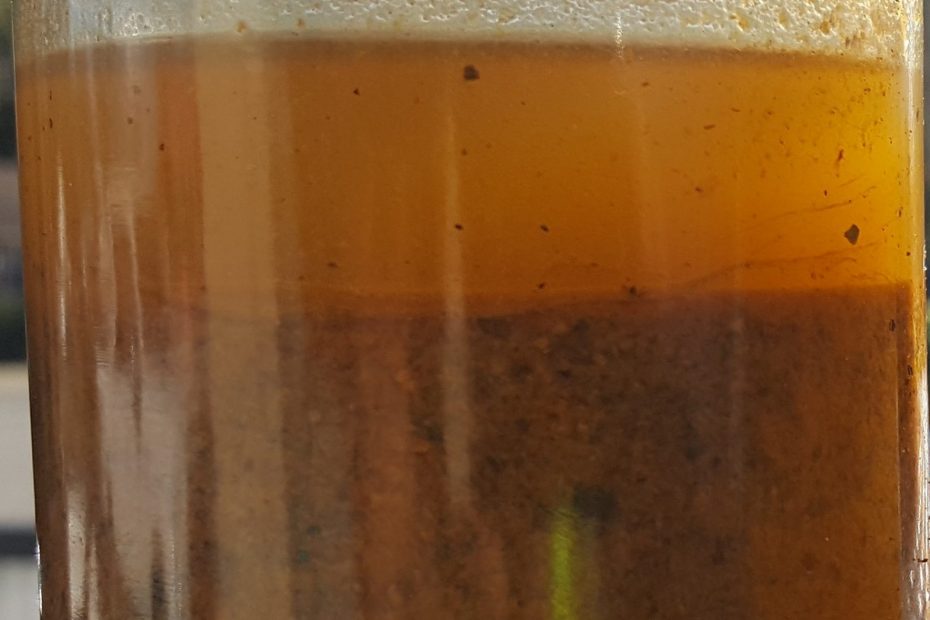

Do you test or sample your fuel regularly? Can you imagine pulling a sample of the fuel in your tank and seeing severe contamination? Many tank owners are experiencing higher maintenance costs on their fuel systems and equipment. Research shows that contaminated fuel accounts for more than a 30% increase in maintenance costs in both fuel systems and engines. Fuel efficiency can drop by more than 25%. Surprisingly, people asked will say they have good fuel quality without really knowing what’s in their tank. Statistically, fuel quality is off spec and substandard, the very reason maintenance costs are high. Do you know the quality of your fuel? Unless you have sampled and tested your fuel, you probably don’t. One thing is certain, the only way to determine fuel quality is sample and test. Knowing is the first step to fuel quality management.

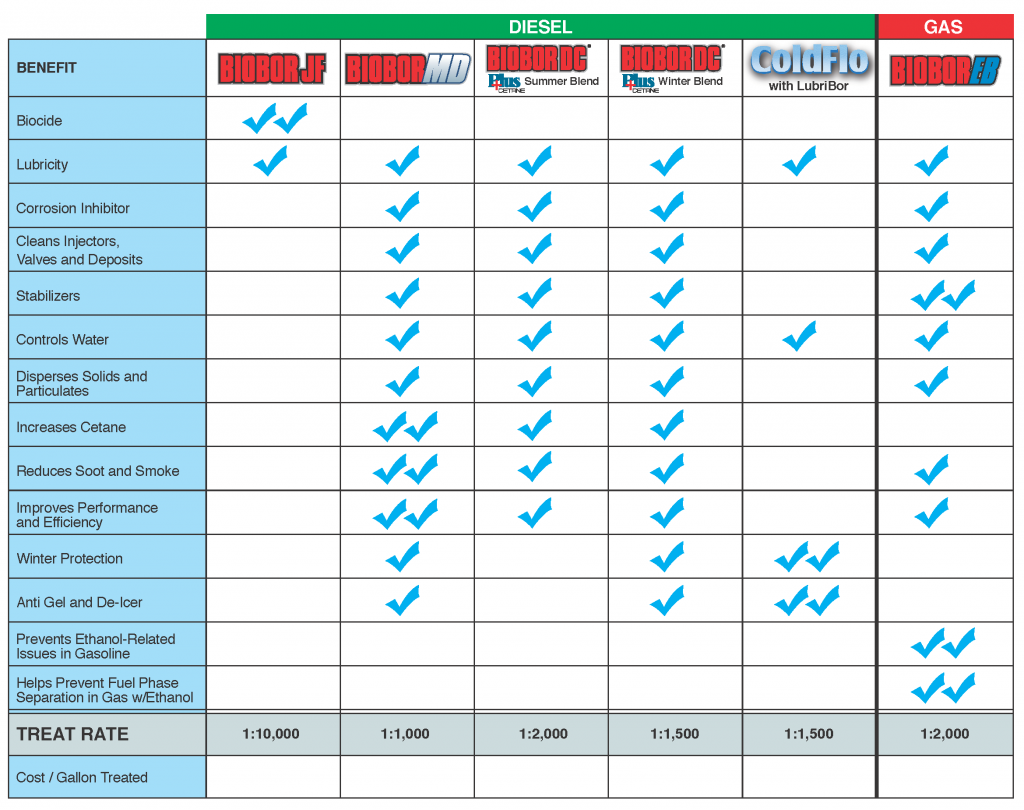

Once the fuel and system are cleaned, an additive program will help to maintain the fuel and equipment, lowering costs and liabilities. Why use additives for fuel quality management. Research shows fuel often arrives off spec. Additives remediate, stabilize, clean and enhance the fuel.

Fuel additives remediate fuel issues and enhances engine performance. When fuel degrades and ages, it loses lubricity, cetane or octane, detergents and stabilizers. Quality additive packages that include the proper formulation help remediate fuel that otherwise may not meet OEM specifications. They can also be used to help reduce system corrosion and stabilize the fuel for longer life and more optimal performance. Without additives, fuel will age to the point of failure especially when fuels are stored for extended periods of time. Additives help save fuel, reduce operating costs, downtime, liabilities and risk.

Even if you filter your fuel and clean your tanks, additives are key to disinfection, remediation and cost savings. You cannot completely decontaminate fuel a fuel system without a biocide. Aged and degraded fuel must be remediated with the right additives. If you operate a fleet, reduce your operating cost by using additive enhances. Better fuel economy, lower emissions and lower costs.

The Biobor® family of products includes diesel fuel and gasoline additives designed to remediate, stabilize, clean and enhance fuel. If you manage fuel and fuel systems, and are not using additives as a way to reduce costs and liabilities contact the Biobor® experts and find out how they can help you develop a personalize FQM program. If you are using non-Biobor® products, contact us and find out why you need to make the change to Biobor®.

Follow BioborShare the Post