FUEL CONTAMINATION

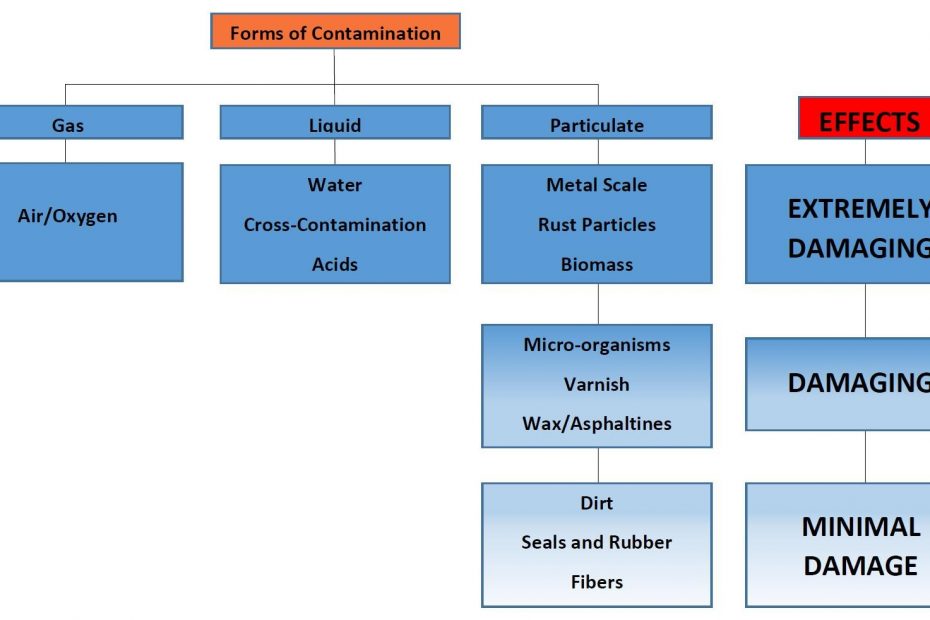

The most common contaminants associated with damage in fuel systems are water, solid particulates and microbes. While microbes are solids, they form a separate category since they are living organisms capable of multiplying and deserve special attention. Different contaminants present varying degrees of potential damage to both fuel and fuel systems as demonstrated in the chart above. Water is the most prevalent and damaging. All fuels contain water, most often found in dissolved form. Undissolved or free water represents a major problem and is most often found in the lower, phase layer in bottoms water or as emulsified droplets and haze suspended in fuel.

When free water is present, microbes will find a home there and multiply quickly – doubling about every 20 minutes. That means in just 7 short hours there will be over 2 million. Give it 1 more hour and there will be over 16 million. Conversely, microbes do not colonize easily in dissolved water. It generally takes a source of oxygen as many are aerobic (requiring oxygen to grow). There are anaerobic microbes (not requiring oxygen). Although rarer, they can also create serious problems in fuel systems. Aerobic microbes only require a small amount of water – a one millimeter drop of free water to sustain one million microbes. While free water is more damaging, dissolved water still affects the stability of fuel causing accelerated aging. Managing for fuel quality involves keeping fuel clean and dry. When found, water should be pumped off immediately. Not all areas of a fuel system are easily accessible for proper sampling – a fact that bears repeating as a helpful reminder. And while electronic probes and water finding paste work, they can and do fail. The presence of water often goes undiscovered. In our next article we will take up the topic of how fuel system anatomy can have a lot to do with proper sampling and fuel maintenance. Note here that there is usually enough water to create a problem and support microbial growth.

Particulate contamination is certain. As fuel is transported, it picks up contamination along the way. Additionally, fuel systems breathe and draw in considerable particulate contamination over time. Airborne particulates enter the fuel through vents and openings accumulating as fuel ages. This includes dirt, organic matter and microbial solids. Fuel exposed to oxygen ages. Oxidation in combination with water and other contaminants causes accelerated oxidative degradation. The process results in the constituent parts of the hydrocarbon molecule breaking apart. The formation of gum and wax sediments and the production of acids and peroxides are all accelerated by microbial contamination.

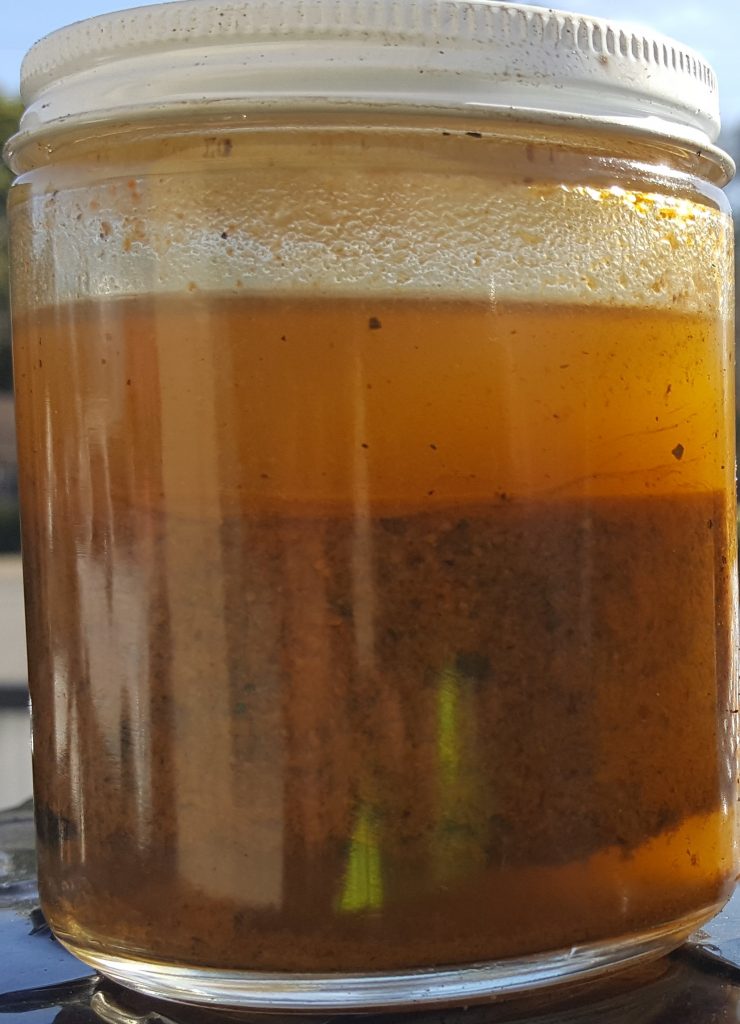

Biomass Contamination

Contamination studies tend to agree that on average, a 10,000-gallon tank that receives an 8,000-gallon delivery of fuel every week will accumulate over 35 pounds of particulate contamination in a year. Condensation also occurs as the tank breathes. An underground storage tank with a much lower temperature than the ambient air outside, receiving a warmer load of fuel will condensate inside the tank. Over time, free water accumulates. As you can see, fuels have to be managed. They will not stay clean and dry by themselves.

Fuel systems are in a constant state of flux, constantly breathing as fuel is pumped in and out. This process continually introduces new contaminants. Microbial contamination is inevitable. Microbes feed off of hydrocarbons. They are often referred to as hydrocarbon utilizing microorganisms or Humbugs. As they eat the fuel, they produce acids enzymes and biomass. The acid settles to the bottom of the tank, mixes with other contaminants forming an environment of sticky mass. Acid formation accelerates the decomposition of fuel especially biodiesel. The molecules of biodiesel are predominantly fatty acid methyl esters (FAME). Its breakdown usually happens slowly unless water is present. The chemical breakdown of FAME by water (hydrolysis) is accelerated in an acidic environment.

The combination of interactions between contaminants play a significant role in accelerating the oxidative instability of the fuel and damaging fuel system components. Accelerated corrosion or microbial influenced corrosion (MIC) are well documented today. Contamination leads to fuel loss, fuel system damage and equipment damage when bad fuel is burned in today’s high performance engines. So, what is the answer – FUEL QUALITY MANAGEMENT. Over the next few articles, we will discuss fuel system anatomy and how to develop a cost savings program. In short, fuel quality management is a risk management approach to fuel and fuel system maintenance. Identifying the problem, finding the solution and implementing a plan. This can include fuel/tank cleaning and fuel system repairs but it always includes the proper use and application of a fuel biocide. As stated, microbial contamination is inevitable! The only sure way to reduce microbes is through the regular use of a quality biocide that is both water and fuel soluble. Biobor JF is the original, industry standard biocide since 1965. Independently tested, EPA registered and OEM approved for use in all hydrocarbons. It does not affect fuel performance and is more stable, less corrosive and safer to handle than other products on the market. It works in both water and fuel unlike many of our competitors. You want to use a biocide that moves through the fuel system with the fuel and continues to kill microbial contamination along the way. Contact us and we can help you!

Follow BioborShare the Post